There are many types of industrial boilers, the quality of coal is very different, the resistance of the dust collector is different, and a series of reasons lead to large differences in the air volume and air pressure of the boiler centrifugal induced draft fan. In order to adapt to this situation, and considering the economy of the boiler induced draft fan, some adjustments have been made to the structure of the fan, so the boiler centrifugal induced draft fan is mainly composed of impeller, casing, air inlet and other structures. There is also a transmission group (composed of main shaft, bearing box, pulley, etc.).

Impeller: It is composed of 12 backward inclined flat blades, made of 16Mn, welded between the arc-conical wheel cover and the flat wheel disc, and has been corrected for static and dynamic balance, running smoothly and high strength.

Casing: It is welded into a volute-shaped whole with steel plates. There is also a dust cleaning door on the volute to facilitate the removal of dust accumulated on the blades and in the casing, ensuring the balance and aerodynamic performance of the impeller.

Air inlet: It is made into a convergent streamlined overall structure and fixed to the side of the casing inlet with bolts.

Adjustment door: The adjustment door is petal-shaped and is axially installed in front of the air inlet. Due to the use of an external transmission structure, the transmission is flexible and convenient. The adjustment range is from 0° (fully open) to 90° (fully closed).

What are the specific aspects of dust ventilation fans in current application production materials?

When we use the fan, we must follow the instructions. First of all, there must be a ground wire during installation, which is also for the sake of safety in future use. One is to reduce some unnecessary troubles. Another point is that the direction of rotation of the fan is specified and it rotates in a clockwise direction. We must pay attention to it when using it. If it rotates counterclockwise, it may not achieve the effect. If the fan fails, we must stop running before debugging and repairing it. The scope of application of the fan is very wide. In fact, we still need to know the specific use value when we understand the product. After all, the value of many products themselves is very high. We can look at the scope of use of this equipment and how it is evaluated in the entire market.

From the perspective of the scope of application alone, it is now more common in metallurgy, petrochemicals, electric power and urban rail transit, because if there is no such equipment, there may be many problems during operation. And the traditional scope of use is also relatively wide, which is enough to show that the product has a wide range of uses.

In the existing market, it is still necessary to choose a better one when choosing a fan. After all, it has been used for a long time and is now being used in many fields. Its main function is ventilation. This is something that must be paid attention to. Only by understanding the product in a timely manner and using it reasonably can you know its actual value.

Processing and forming process of dust extractor fan impeller

In order to ensure that the fan impeller has excellent strength, air tightness and other comprehensive performance, and considering the processing feasibility, the blades and the wheel disc are first welded together according to the drawing plan to ensure that the blades are rooted reliably; then they are shaped and stress-relieved annealing is performed; then the blades and the wheel cover are installed with a plug welding groove with a positioning structure and connected with a plug welding seam; then they are shaped and stress-relieved annealing is performed; and finally they are processed and formed.

The key to the technology is to weld the processed blades to the wheel disc according to the fillet weld; then the wheel cover after stamping is milled into a through hole according to the position and shape of the blade, and then the wheel cover is covered on the blade, so that the blade is inserted into the through hole of the wheel cover, and plug welding is performed from the outside.

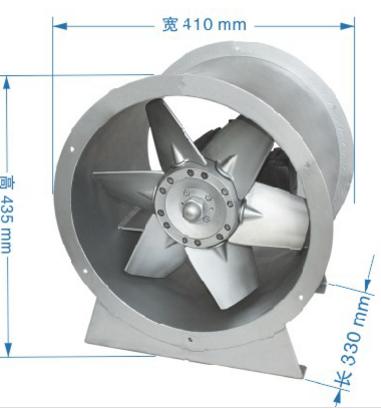

Industrial dust extractor fan

In order to ensure the appearance size, the strength of the weld and the balance performance of the impeller, the depth of the blade in the wheel cover plug welding groove should not be too large. This size is controlled at 1/3 of the wheel cover thickness. When milling the welding groove on the wheel cover, the groove width should not be too large or too small. If it is too large, the blades will deform during assembly or welding and deviate from the original position, affecting the dynamic balance performance of the impeller; if it is too small, it will cause assembly difficulties.

When welding, the welding should be performed symmetrically in sections as much as possible. For areas with a temperature exceeding 350℃, excellent hydrogen protection should be performed, and the filling amount of welding wire should be strictly controlled during the welding of each blade to ensure the balance performance requirements of the impeller.

The structure of the dust exhaust fan will cause a lot of fluidity

The structure of the dust exhaust fan will cause great fluidity, which is related to the use effect of the relevant level. Once the axial uniformity and radial uniformity of the flow field are destroyed, it will arouse the phenomenon of strong unsteady flow such as stall change, which will directly affect the safety stability of the parts.

In addition to being affected by these factors, the use efficiency of the commercial dust extractor fan also requires a detailed understanding of the type and model of the fan. Different types of fans have different methods to improve the fan's air extraction efficiency. This also requires users to identify and use, so as to choose an appropriate method to help users improve the overall use efficiency of centrifugal fans.