CF Series Forward Curved Impellers Centrifugal Fan Blower

CF Series centrifugal fan is often used in kitchen exhaust and fume extraction, suitable for ventilation and fume extraction in public places such as canteen, hotel, restaurant , and so on.

CF Series centrifugal fan is often used in kitchen exhaust and fume extraction, suitable for ventilation and fume extraction in public places such as canteen, hotel, restaurant , and so on.

The FC series industrial window exhaust fan is compact in design, small in size and light in weight, and is especially suitable for arrangement in limited space.

The SF Series tube axial fan is an efficient, low noise ventilation equipment, widely used in a variety of ventilation, heat dissipation and noise control scenarios.

Guangdong Gaoze Ventilation Equipment Co.,Ltd.

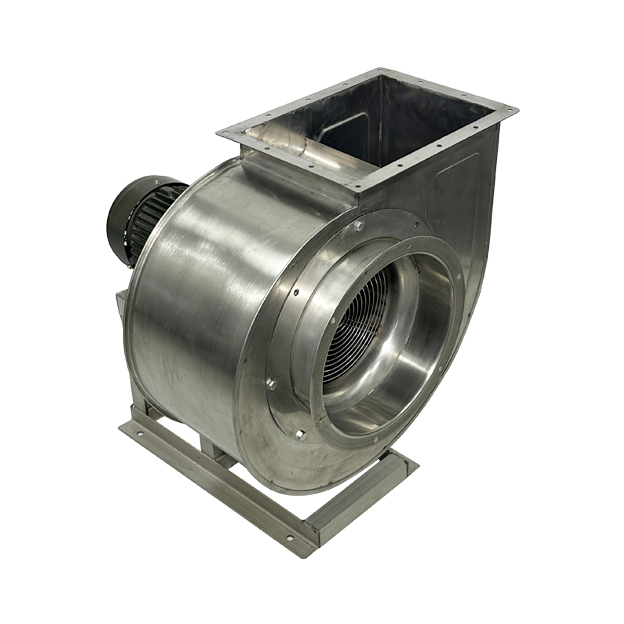

11-62 Series 304 Stainless Steel Multi-blade Centrifugal Fan

1.Typical Feature and Application

11-62 stainless steel centrifugal fan is made of 304 stainless steel material, with strong corrosion resistance. Under extreme conditions, stainless steel centrifugal fans can maintain stable performance and are not easy to damage during long-term operation.

11-62 stainless steel centrifugal fan with forward curved multi-wing impeller, low noise, suitable for quiet environment.

11-62 stainless steel centrifugal fan has the characteristics of high efficiency and large air volume, which is suitable for occasions with large air volume.

11-62 stainless steel stand up fan has 250mm, 280mm, 300mm, 350mm, 400mm, 450mm, 500mm, 600mm, eight different sizes, can be customized different sizes.

2. Performance Range

Fan Type | 11-62 Series 304 Stainless Steel Multi-blade Centrifugal Fan |

Certificate | CE,CCC |

Electricity Current Type | AC(Alternating Current) |

Voltage | 380V |

Frequency | 50HZ |

Power | 0.55KW-5.5KW |

Speed | 960-1450RPM |

Air Volume | 1250m³/h up to 14000 m³/h |

Motor | Standard Motor |

3.Product Description

Stainless steel industrial centrifugal fan is a highly efficient ventilation equipment designed for harsh industrial environments. Made of 304 stainless steel, it has excellent corrosion resistance, high temperature resistance and oxidation resistance. It is suitable for corrosive gas emission scenarios such as food processing, chemical industry, electroplating and medicine. Its precision stamping blade and volute design ensures large air volume and high static pressure output, and the operating efficiency is more than 15% higher than that of ordinary fans. Structure adopts modular design, equipped with explosion-proof motor (optional), sealed bearing seat and shock-proof base, support horizontal/vertical multi-angle installation, easy maintenance.

4.Fan Operation

The optimal installation position of 11-62 industrial centrifugal fan should be determined according to the characteristics of the working environment and actual needs.

According to the specific model and size of 11-62 industrial centrifugal fan, select the appropriate support device for installation. Ensure that the support structure is stable and prevents tilting or shaking.

According to the actual demand, the appropriate pipe is selected to connect with the 11-62 industrial centrifugal fan. Pipe connections must be tight and secure to avoid gas leakage and pressure loss.

After the installation of the 11-62 industrial centrifugal fan, the Angle of the exhaust blade can be adjusted according to the specific needs.

The final step is to connect the power supply to the 11-62 industrial centrifugal fan. Before switching on the power supply, be sure to confirm the stability and reliability of the power supply to ensure the normal operation of the centrifugal fan.

5.Fan Maintain

Regularly clean the inside and outside of the 11-62 steel extractor fan to prevent ash accumulation.

Regularly check whether the motor and transmission parts of 11-62 centrifugale ventilator are working properly, and replace the worn parts in time.

Regularly add lubricating oil to the lubricating transmission parts of the 11-62 stainless steel centrifugal fan to reduce friction and wear.

6.Technical Specification

Model (No.) | Voltage | Power | Revolution | Air Flow | Wind pressur | Noise | Weight |

| (V) | (KW) | (rpm) | (m3/h) | (Pa) | (dB) | (KG) | |

| 2.5A | 220/380 | 0.55 | 1450 | 1250 | 300 | 70 | 25 |

| 2.8A | 220/380 | 0.75 | 1450 | 2300 | 340 | 72 | 30 |

| 3A | 220/380 | 1.5 | 1450 | 4200 | 450 | 74 | 38 |

| 3.5A | 220/380 | 3 | 1450 | 6000 | 800 | 78 | 65 |

| 4A | 380 | 5.5 | 1450 | 9681 | 1053 | 85 | 100 |

| 4A | 380 | 2.2 | 960 | 7500 | 520 | 74 | 90 |

| 4.5A | 380 | 3 | 960 | 8700 | 580 | 76 | 95 |

| 5A | 380 | 4 | 960 | 10000 | 670 | 78 | 125 |

| 6A | 380 | 5.5 | 9 | 14000 | 890 | 80 | 190 |

7.Packing Detail

Film Packing: a cost-effective packing method, it is suggested when order is one full container.

Plywood Box Packing: more safe packing, it is suggested when order is not enough one full container.