CF Series Forward Curved Impellers Centrifugal Fan Blower

CF Series centrifugal fan is often used in kitchen exhaust and fume extraction, suitable for ventilation and fume extraction in public places such as canteen, hotel, restaurant , and so on.

CF Series centrifugal fan is often used in kitchen exhaust and fume extraction, suitable for ventilation and fume extraction in public places such as canteen, hotel, restaurant , and so on.

The FC series industrial window exhaust fan is compact in design, small in size and light in weight, and is especially suitable for arrangement in limited space.

The SF Series tube axial fan is an efficient, low noise ventilation equipment, widely used in a variety of ventilation, heat dissipation and noise control scenarios.

Guangdong Gaoze Ventilation Equipment Co.,Ltd.

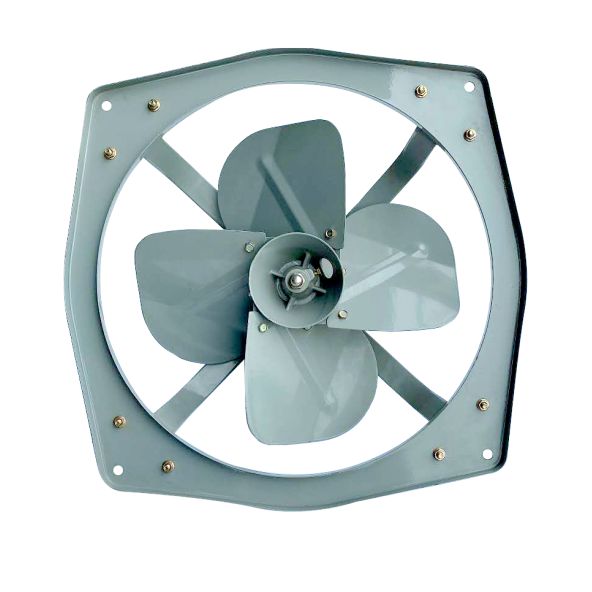

Heavy Duty Industrial Exhaust Fan

1.Typical Feature and Application

The heavy duty exhaust fan can quickly discharge the stuffy air and harmful gases in the room, and the volume of exchange can be up to 98%, effectively improving the indoor air quality.

The heavy duty exhaust fan support 220-240V voltage, no three-phase circuit transformation, reduce the installation threshold and cost, suitable for small and medium-sized places directly used.

The heavy duty exhaust fan is equipped with IP44 protection grade motor as standard, supporting 8-10 hours of continuous operation every day, and maintenance only requires regular cleaning.

This series of heavy duty exhaust fan is suitable for industrial plant, reception room, office, kitchen and other places to meet different ventilation needs.

2. Performance Range

Fan Type | Heavy Duty Industrial Exhaust Fan |

Certificate | CE,CCC |

Electricity Current Type | AC(Alternating Current) |

Voltage | 220V-240V |

Frequency | 50HZ |

Power | 100W-350W |

Speed | 1350RPM |

Air Volume | 2800m³/h up to 6300 m³/h |

Motor | Standard Motor |

3.Product Description

This series of heavy duty exhaust fan is designed for small and medium-sized industry, the product covers 300mm, 380mm, 450mm, 600mm four specifications, suitable for different space requirements of 30㎡ to 150㎡, corresponding power 100W-350W, air volume up to 2800-6300m³/h, can efficiently discharge dust, hot air and light soot.

The heavy duty exhaust fan supports 220-240V single-phase voltage power supply, eliminating the cost of three-phase circuit transformation and greatly reducing the installation threshold. The body adopts stamped steel blade and reinforced cast iron frame, the structure is stable and resistant to impact, and the standard IP44 protection grade motor is equipped.

It is suitable for dining kitchen, underground garage, storage workshop, farm and other scenes, especially suitable for the environment without strong corrosion and non-explosion-proof.

4.Fan Operation

The heavy duty exhaust fan should be installed near the oil smoke and water vapor source, and ensure that there is an independent ventilation channel or directly outside.

Align the heavy duty exhaust fan with the holes in the support and secure the fan using bolts (shockproof gaskets are recommended) to ensure that the fusel is stable and does not shake.

Connect power cables to the heavy duty exhaust fan cables, and ensure that the phase, neutral, and ground cables are correctly connected.

After the power is switched on, start the heavy duty exhaust fan, observe whether the fan blade is correctly turned (generally exhaust air to the outside), detect whether the noise and vibration are abnormal, and measure whether the actual air volume is up to standard.

5.Fan Maintain

Heavy duty industrial exhaust fan maintenance includes cleaning, lubrication, avoid high temperature and direct sunlight.

Since the Heavy duty industrial exhaust fan will accumulate oil and dust during work, it needs to be cleaned regularly.

When cleaning the exterior exhaust fan, care should be taken to avoid using corrosive chemical solutions, so as not to damage the plastic parts and outer paint.

Regular lubrication of the motor and the blades can reduce friction and extend the service life of the 18 inch exhaust fan.

6.Technical Specification

Model (No.) | Size | Voltage | Power | Revolution | Air Flow | Noise | Weight |

(V) | (W) | (rpm) | (m3/h) | (dB)A | (KG) | ||

GH-300 | 300mm (12") | 220-240 | 100 | 1350 | 2800 | 67 | 7 |

GH-380 | 380mm (14") | 220-240 | 160 | 1350 | 4500 | 72 | 8 |

GH-450 | 450mm (18") | 220-240 | 250 | 1350 | 5400 | 78 | 11 |

| GH-500 | 500mm (20") | 220-240 | 280 | 1350 | 5850 | 76 | 12 |

| GH-600 | 600mm(24") | 220-240 | 350 | 1350 | 6300 | 79 | 19 |

7.Packing Detail

Film Packing: a cost-effective packing method, it is suggested when order is one full container.

Carton Packing: standard packing ,it is suggested when order is one full container.

Plywood Box Packing: more safe packing, it is suggested when order is not enough one full container.