CF Series Forward Curved Impellers Centrifugal Fan Blower

CF Series centrifugal fan is often used in kitchen exhaust and fume extraction, suitable for ventilation and fume extraction in public places such as canteen, hotel, restaurant , and so on.

CF Series centrifugal fan is often used in kitchen exhaust and fume extraction, suitable for ventilation and fume extraction in public places such as canteen, hotel, restaurant , and so on.

The FC series industrial window exhaust fan is compact in design, small in size and light in weight, and is especially suitable for arrangement in limited space.

The SF Series tube axial fan is an efficient, low noise ventilation equipment, widely used in a variety of ventilation, heat dissipation and noise control scenarios.

Guangdong Gaoze Ventilation Equipment Co.,Ltd.

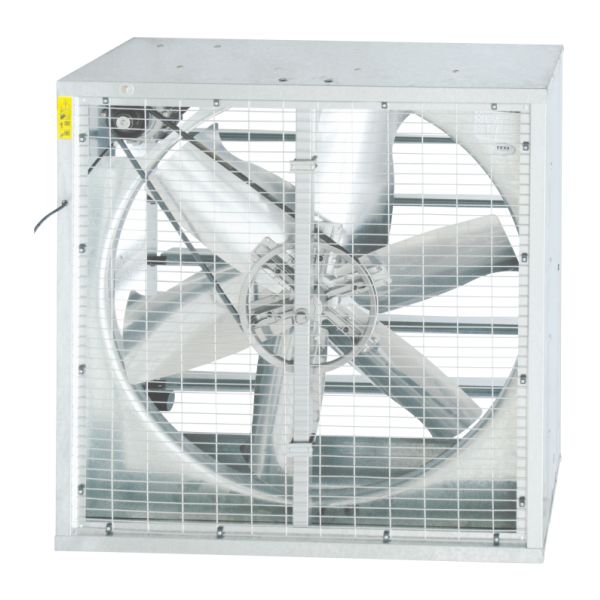

LF Negative Pressure Exhaust Fan Ventilator

1.Typical Feature and Application

The Negative pressure fan uses high efficiency motor, low energy consumption, low operating cost, and reduces the dependence on air conditioning, which meets the requirements of energy saving and environmental protection.

In a high temperature environment, the Negative pressure fan can quickly discharge hot air, introduce cool air, effectively reduce the indoor temperature, suitable for workshops, farms and other places.

The design of the Negative pressure fan is simple, the main components include the motor, the fan blade and the shell, the installation and maintenance is simple, the failure rate is low, and the daily maintenance cost is low.

The Negative pressure fan uses a low noise motor and optimized blade design, which provides low noise during operation and is suitable for places requiring quiet environment.

2. Performance Range

Fan Type | LF Negative Pressure Exhaust Fan Ventilator |

Certificate | CE,CCC |

Electricity Current Type | AC(Alternating Current) |

Voltage | 380V |

Frequency | 50HZ |

Power | 0.37KW-1.1KW |

Speed | 500-450RPM |

Air Volume | 26000m³/h up to 44500 m³/h |

Motor | Standard Motor |

3.Product Description

Negative pressure fan is a kind of efficient ventilation equipment, widely used in industrial, agricultural and commercial fields, through a strong pumping capacity to quickly discharge indoor air, forming a negative pressure environment, promote fresh air inflow, to achieve efficient ventilation and significant cooling effect, especially suitable for large workshops, underground parking lots, warehouses, greenhouses and farms and other places. It is an efficient, energy-saving and durable ideal ventilation equipment.

4.Fan Operation

Choose the right location, usually the Greenhouse exhaust fan is installed on the wall or window, to ensure smooth ventilation and avoid obstacles.

Fasten the support to the wall or window frame using screws, and calibrate the support using a level to ensure that it is level.

Place the Greenhouse exhaust fan on the bracket, fix it with screws, and use sealant to seal the contact point between the fan and the wall to prevent air leakage.

Connect the power supply, check whether the circuit meets the requirements, connect the cables correctly according to the wiring diagram, and make sure that the shell of the Greenhouse exhaust fan is grounded to ensure safety.

After the installation is completed, debug and run, start the machine to test whether the Greenhouse exhaust fan runs smoothly, check whether there is abnormal noise or vibration, and use the anemometer to confirm whether the wind speed is up to the standard.

5.Fan Maintain

Regularly check the operating status of the greenhouse vent fan, clean up dust and debris, and ensure that the fan is clean.

Regularly check whether the screw of the Greenhouse exhaust fan is loose to ensure long-term efficient operation of the fan.

Regular lubrication and maintenance to ensure smooth operation of moving parts such as bearings.

6.Technical Specification

Model (No.) | Voltage | Power | Revolution | Air Flow | Noise | Weight |

| (V) | (KW) | (rpm) | (m3/h) | dB(A) | (KG) | |

800 | 380 | 0.37 | 500 | 26000 | 40 | 23 |

| 900 | 380 | 0.37 | 520 | 28000 | 40 | 26 |

| 1060 | 380 | 0.55 | 500 | 32500 | 50 | 32 |

| 1220 | 380 | 0.75 | 480 | 37500 | 60 | 38 |

| 1380 | 380 | 1.1 | 450 | 44500 | 63 | 43 |

| 1530 | 380 | 1.5 | 450 | 49000 | 68 | 58 |

7.Packing Detail

Film Packing: a cost-effective packing method, it is suggested when order is one full container.

Plywood Box Packing: more safe packing, it is suggested when order is not enough one full container.