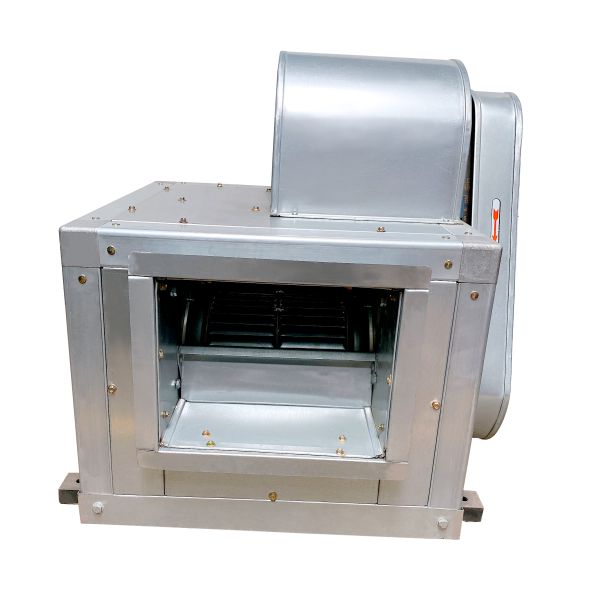

CF Series Forward Curved Impellers Centrifugal Fan Blower

CF Series centrifugal fan is often used in kitchen exhaust and fume extraction, suitable for ventilation and fume extraction in public places such as canteen, hotel, restaurant , and so on.

CF Series centrifugal fan is often used in kitchen exhaust and fume extraction, suitable for ventilation and fume extraction in public places such as canteen, hotel, restaurant , and so on.

The FC series industrial window exhaust fan is compact in design, small in size and light in weight, and is especially suitable for arrangement in limited space.

The SF Series tube axial fan is an efficient, low noise ventilation equipment, widely used in a variety of ventilation, heat dissipation and noise control scenarios.

Guangdong Gaoze Ventilation Equipment Co.,Ltd.

YFJ Series Fire Smoke Exhaust Ventilation Cabinet Centrifugal Fan

1.Typical Feature and Application

The YFJ series cabinet exhaust fan has the characteristics of high efficiency and low noise, which can ensure efficient operation and reduce the noise pollution to the surrounding environment.

The structure design of the YFJ series cabinet exhaust fan is compact and beautiful. The box body is assembled with the frame and the box board. The inner layer is noise reduction material to further reduce the noise.

The installation and maintenance of the YFJ series cabinet exhaust fan is relatively simple and convenient, which is suitable for the ventilation and smoke exhaust needs of various places, and is widely used in hotels, restaurants, theaters, basements, factories and mining enterprises.

The YFJ series cabinet exhaust fan is divided into two types, type A and type B, type A motor is installed outside the box for fire smoke exhaust; Type B motor is installed in the box for ventilation.

YFJ series cabinet exhaust fan are available in eleven sizes of 9#, 10#, 12#, 15#, 18#, 20#, 22#, 25#, 28#, 30#, 33#.

2. Performance Range

Fan Type | YFJ Series Fire Smoke Exhaust Ventilation Cabinet Centrifugal Fan |

Certificate | CE,CCC |

Electricity Current Type | AC(Alternating Current) |

Voltage | 380V |

Frequency | 50HZ |

Power | 0.55KW-30KW |

Speed | 450-1200RPM |

Air Volume | 1800m³/h up to 67000 m³/h |

Motor | Standard Motor |

3.Product Description

The YFJ cabinet ventilation fan is a kind of ventilation equipment with high efficiency and low noise. It is widely used in various places for ventilation and smoke exhaust. Its main components include a low noise forward tilt multi-wing centrifugal fan, a motor, a bearing, a transmission part and a silencer box. cabinet ventilation fan provide 12 different Angle inlet and outlet positions to meet the needs of different installation environments.

4.Fan Operation

The YFJ Cabinet ventilation fan need to be installed on a firm and stable basis to ensure the stability and safety of the fan.

The YFJ Cabinet ventilation fan needs to be installed with a special support, and the structure and size of the support must meet the requirements of the fan.

The installation of the YFJ Cabinet ventilation fan motor needs to meet the requirements, the motor and the fan axis should be kept parallel, the motor and the fan coupling should be installed, the displacement of the coupling should be adjusted, and the two ends of the coupling should be aligned.

The pipe installation of the inlet and outlet of the YFJ Cabinet ventilation fan needs to be consistent with the caliber of the fan, and the connection of the inlet and outlet should be firm to prevent air leakage.

After the YFJ Cabinet ventilation fan is installed, check the rotation direction, vibration, noise, current, and voltage of the fan during commissioning to ensure the normal operation of the fan.

5.Fan Maintain

Regularly clean the inside and outside of the YFJ Series industrial box fan to prevent ash accumulation.

Regularly check whether the motor and transmission parts of YFJ Series cabinet fan are working properly, and replace the worn parts in time.

Regularly add lubricating oil to the lubricating transmission parts of the YFJ Series cabinet blower to reduce friction and wear.

6.Technical Specification

Model (No.) | Power | Revolution | Air Flow | Wind pressure | Noise |

| (KW) | (rpm) | (m3/h) | (Pa) | dB(A) | |

| 9# | 0.55 | 1000 | 1800-3300 | 250-160 | ≤62 |

| 0.75 | 1100 | 2200-3700 | 280-210 | ≤62 | |

| 1.1 | 1200 | 2600-4300 | 320-250 | ≤62 | |

| 10# | 0.75 | 900 | 2800-4600 | 420-310 | ≤65 |

| 1.1 | 1000 | 3000-5000 | 480-380 | ≤65 | |

| 1.5 | 1100 | 3200-5600 | 570-450 | ≤65 | |

| 12# | 1.1 | 900 | 3600-6200 | 520-420 | ≤68 |

| 1.5 | 1000 | 4200-7000 | 620-740 | ≤68 | |

| 2.2 | 1100 | 5200-8100 | 700-500 | ≤68 | |

| 15# | 1.5 | 720 | 5600-8500 | 500-400 | ≤70 |

| 2.2 | 850 | 6800-9300 | 600-480 | ≤70 | |

| 3 | 900 | 7500-12000 | 680-550 | ≤70 | |

| 18# | 2.2 | 600 | 7733-13007 | 284-176 | ≤71 |

| 3 | 760 | 8200-13000 | 470-390 | ≤71 | |

| 4 | 800 | 9600-15000 | 540-450 | ≤71 | |

| 20# | 3 | 560 | 9196-15469 | 290-200 | ≤72 |

| 4 | 720 | 12000-18000 | 470-350 | ≤72 | |

| 5.5 | 760 | 13000-19000 | 650-460 | ≤72 | |

| 7.5 | 800 | 14000-21000 | 700-550 | ≤73 | |

| 22# | 4 | 600 | 14026-23590 | 422-273 | ≤73 |

| 5.5 | 650 | 15000-22000 | 630-460 | ≤73 | |

| 7.5 | 720 | 17000-25000 | 680-520 | ≤75 | |

| 11 | 800 | 19000-28000 | 780-570 | ≤75 | |

| 25# | 5.5 | 520 | 16896-28416 | 373-219 | ≤75 |

| 7.5 | 650 | 20000-30000 | 620-470 | ≤75 | |

| 11 | 720 | 21000-34000 | 690-520 | ≤75 | |

| 15 | 760 | 23000-37000 | 720-550 | ≤77 | |

| 28# | 7.5 | 500 | 21224-35696 | 438-297 | ≤77 |

| 11 | 600 | 24000-40000 | 580-460 | ≤77 | |

| 15 | 650 | 26000-43000 | 660-520 | ≤77 | |

| 18.5 | 720 | 29000-46000 | 710-560 | ≤80 | |

| 30# | 11 | 520 | 27958-47022 | 551-341 | ≤80 |

| 15 | 580 | 31000-52000 | 600-450 | ≤80 | |

| 18.5 | 600 | 33000-55000 | 680-510 | ≤80 | |

| 22 | 650 | 36000-60000 | 750-590 | ≤82 | |

| 33# | 15 | 450 | 31320-51530 | 545-367 | ≤82 |

| 18.5 | 500 | 38000-61000 | 630-500 | ≤82 | |

| 22 | 560 | 42000-64000 | 700-550 | ≤82 | |

| 30 | 600 | 44000-67000 | 780-600 | ≤85 |

7.Packing Detail

Film Packing: a cost-effective packing method, it is suggested when order is one full container.

Plywood Box Packing: more safe packing, it is suggested when order is not enough one full container.